Why Cold Chain Logistics Could Be the Difference Between Life and Death

In the pharmaceutical industry, ensuring the safe and effective delivery of medicines, vaccines, and other medical supplies isn’t just a matter of convenience—it’s a matter of life and death. Cold chain logistics is essential for transporting temperature-sensitive products that require strict temperature control from the manufacturing facility to the end user. Without it, many of the life-saving treatments we rely on could become ineffective, dangerous, or even deadly.

What Is Cold Chain Logistics?

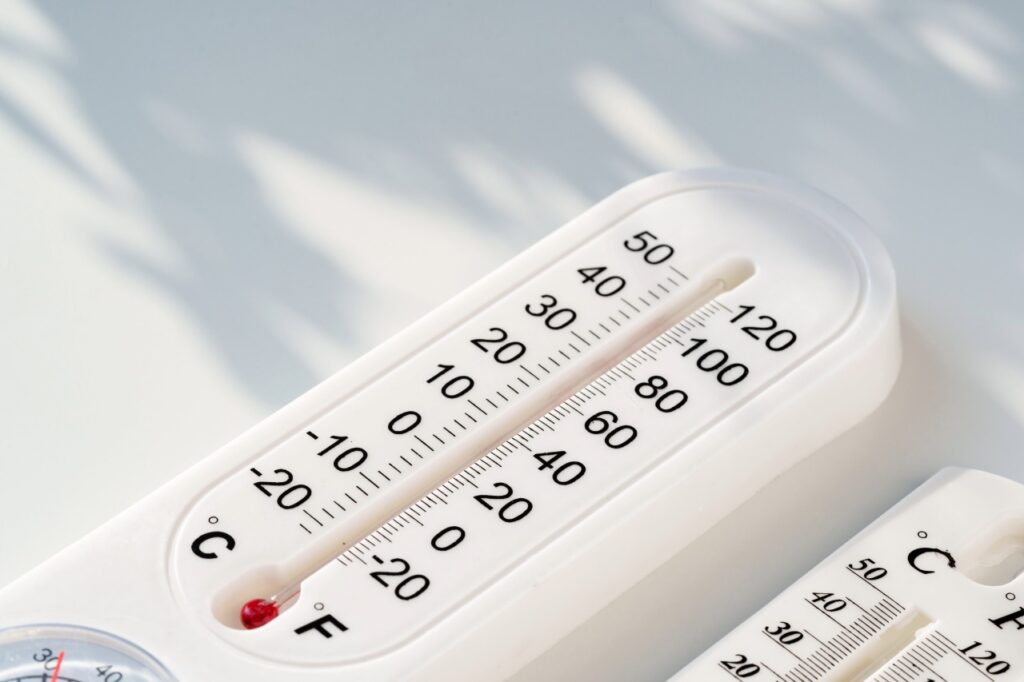

Cold chain logistics refers to the process of storing and transporting products that must be kept within a specific temperature range throughout the supply chain. This could mean keeping products refrigerated at 2°C to 8°C (35°F to 46°F), or frozen at -20°C (-4°F) or even colder. Maintaining these temperatures ensures that pharmaceuticals, vaccines, biologics, and other temperature-sensitive products maintain their efficacy and safety.

The Science Behind It

Many pharmaceutical products, including vaccines, insulin, and certain cancer treatments, are biologically active. This means that they are made up of molecules that can easily break down or degrade if exposed to the wrong temperature. Cold chain logistics is all about preserving these delicate products from the point of manufacture to the end user, ensuring they arrive in the condition needed to be effective.

Why Is Cold Chain Logistics So Important for Pharmaceuticals?

- Ensuring Drug Efficacy and Safety

Medicines and vaccines can lose their potency if not stored and transported under the right conditions. This means that a patient could receive a treatment that is less effective or even completely ineffective, leading to potential health risks. In some cases, such as vaccines, improper storage can render the product dangerous.

- Regulatory Compliance

The pharmaceutical industry is heavily regulated, with strict guidelines on how drugs must be manufactured, stored, and transported. Regulatory bodies like the FDA in the United States and the EMA in Europe have stringent requirements for cold chain logistics to ensure product safety and quality. Failing to comply can lead to legal repercussions, product recalls, and severe financial losses. - Maintaining Supply Chain Integrity

A break in the cold chain could lead to contamination, loss of efficacy, or product waste. Maintaining a robust cold chain logistics system ensures the integrity of the supply chain, reduces waste, and helps manage costs. With the rise of biologics and personalized medicines, which are often more temperature-sensitive than traditional drugs, the need for reliable cold chain logistics has never been greater.

Challenges in Cold Chain Logistics

- Temperature Control and Monitoring

Keeping products at the right temperature throughout the journey can be a significant challenge. Even a slight deviation can compromise product quality. This is why continuous temperature monitoring, using data loggers and real-time sensors, is critical to ensure products remain within the required temperature range. - Infrastructure and Transportation

Transporting temperature-sensitive products requires specialized vehicles, containers, and equipment. Not all regions have the infrastructure to support cold chain logistics, especially in remote areas. The need for consistent refrigeration or freezing capability from the point of departure to the final destination can increase transportation costs and complexity. - Risk of Delays and Supply Chain Disruptions

Delays are an inevitable part of logistics, but they can be catastrophic for temperature-sensitive products. Unexpected delays due to customs, weather, or mechanical issues can lead to temperature excursions, affecting the quality of pharmaceuticals. Cold chain logistics companies must have contingency plans in place, including backup refrigeration and alternative routes, to manage these risks.

Solutions to Overcome Cold Chain Logistics Challenges

- Advanced Temperature Monitoring Systems

Companies are investing in advanced monitoring systems that provide real-time data on the temperature and location of products throughout the supply chain. These systems use GPS tracking and IoT devices to send alerts if there is a risk of temperature deviation, allowing for immediate corrective actions. - Specialized Packaging Solutions

Using high-quality insulated containers and phase change materials can help maintain the desired temperature range during transit. Advanced packaging solutions are designed to withstand different climate conditions and protect products during long-haul journeys, ensuring they reach their destination in optimal condition. - Building Redundant Supply Chains

To mitigate risks, pharmaceutical companies often build redundant supply chains. This means having multiple suppliers and logistics partners that can step in if the primary supply chain is disrupted. Redundancy helps to ensure that temperature-sensitive products can still be delivered, even if one link in the supply chain fails.

Real-World Examples: Success Stories in Cold Chain Logistics

- COVID-19 Vaccine Distribution

One of the most significant cold chain logistics challenges in recent history was the global distribution of COVID-19 vaccines. Some of these vaccines required ultra-cold storage at temperatures as low as -70°C (-94°F). Logistics companies had to quickly adapt to distribute these vaccines worldwide, ensuring they arrived safely at clinics and hospitals. Companies that succeeded did so by investing in ultra-cold freezers, real-time monitoring, and rapid distribution networks. - Insulin Supply Chains

Insulin is another example of a product that relies heavily on cold chain logistics. Insulin must be kept cool, but not frozen, throughout its journey from the manufacturer to the patient. Effective cold chain logistics ensures that diabetics receive insulin that is safe and effective, regardless of where they are in the world.

The Future of Cold Chain Logistics in Pharmaceuticals

- Expansion of Biologic Drugs and Personalized Medicine

The demand for biologic drugs, which are more sensitive to temperature changes than traditional drugs, is increasing. This growth is driving the need for more sophisticated cold chain logistics solutions. Additionally, personalized medicine, which often involves tailored treatments produced in small batches, requires highly reliable cold chain systems to ensure the precise delivery of individualized therapies. - Innovations in Temperature-Control Technology

The future of cold chain logistics will likely see the integration of more advanced technologies, including AI and blockchain, to enhance visibility and traceability. AI can predict potential risks, allowing companies to take preventive measures, while blockchain ensures that data integrity is maintained throughout the supply chain, providing an unbroken chain of custody.

Conclusion: Cold Chain Logistics Is the Backbone of the Pharmaceutical Industry

The role of cold chain logistics in the pharmaceutical industry cannot be overstated. Without effective cold chain systems, many life-saving treatments would not reach the people who need them. Ensuring products are stored, transported, and delivered within the correct temperature range is crucial for maintaining drug efficacy, safety, and regulatory compliance. As the industry grows, the need for reliable, efficient, and innovative cold chain logistics solutions will only become more critical.